Products

Calcium Sulphate Core Panel

Calcium Sulphate Raised Floor

Wood Core Raised Floor

Steel Raised Floor

Ceramic Finish Raised Floor

Aluminum Raised Floor

Airflow Raised Floor

Glass Viewing Panel

Accessories

Raised Floor Finishes

Anti-static Raised Access Floor

Data Center Raised Floor

Office Building Raised Floor

Residential Raised Floor Systems

Customized Raised Floor

Saw machine for raised floor

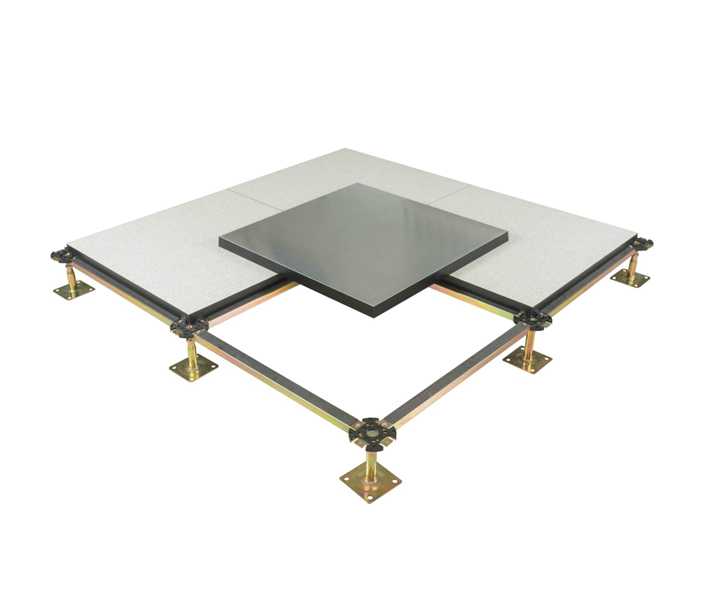

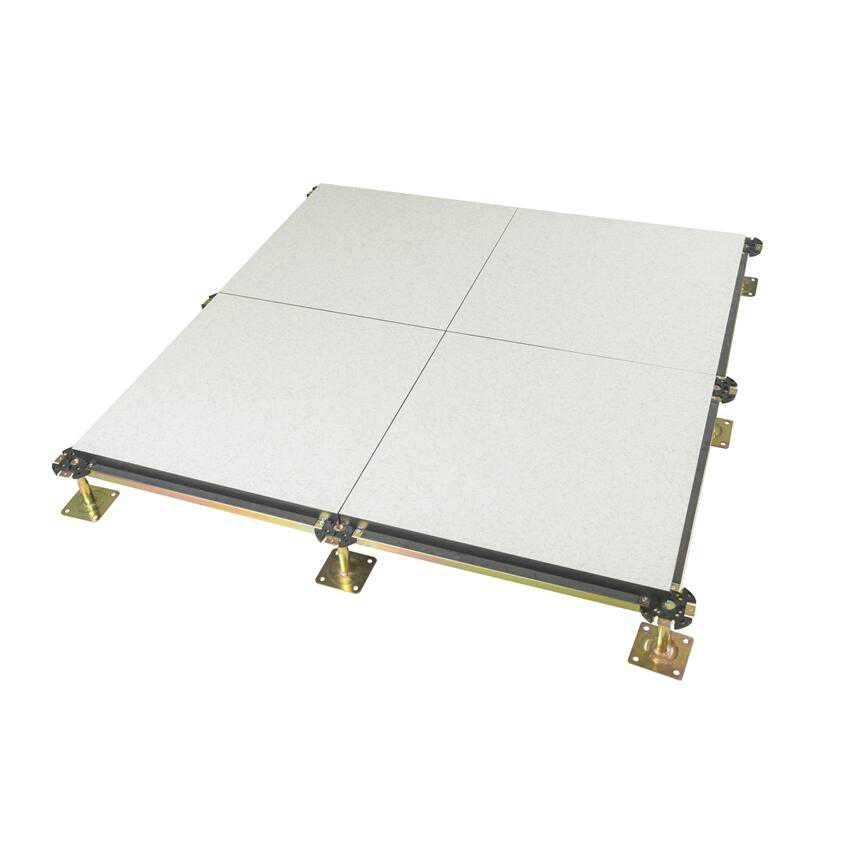

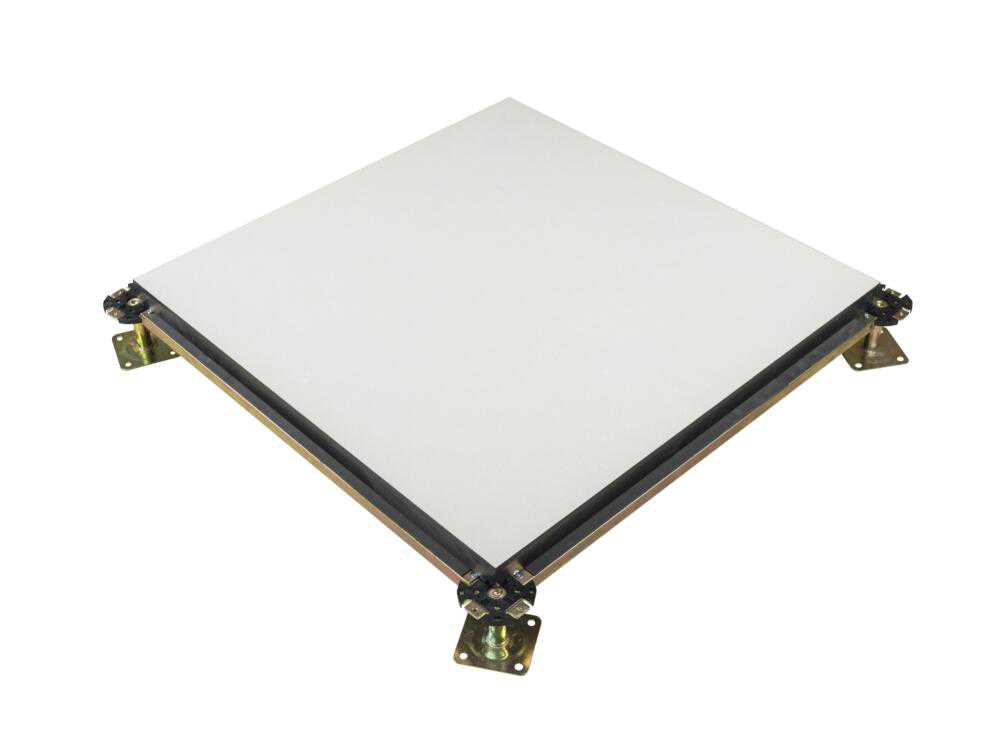

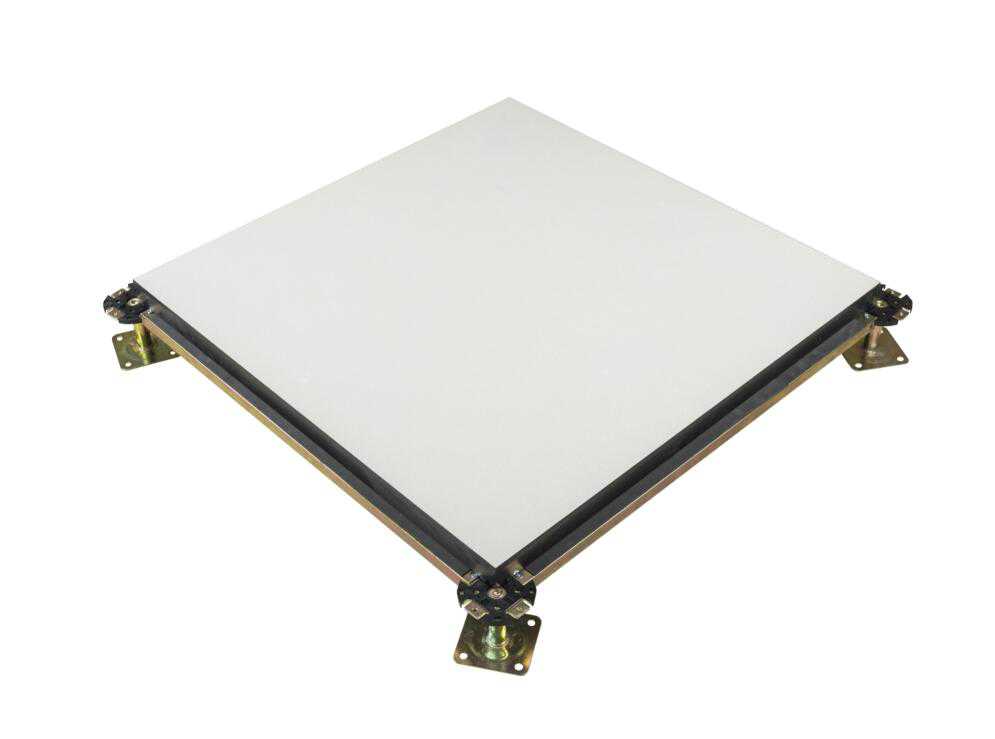

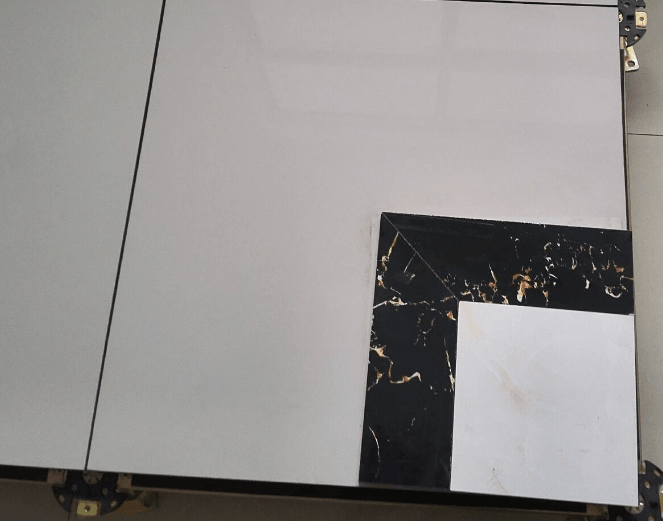

Ceramic Finish Calcium Sulphate raised floor

Abeite Calcium Sulphate Raised Floor is hot selling product, it’s made by 100% green environmental protection natural gypsum powder. From the selection of materials, procurement, production, packaging, are following the Chinese and PSA MOB PS/SPU、DIN EN 12825 specifications. With the German brands Mero and Lindner as the goal, to provide our customers with high-quality products.

Type: | FS662-1500 |

Finished Floor Height: | 70-2000mm |

Panel Size: | 600*600mm、800*800mm and special size |

Ceramic Thickness: | 10/12mm |

Ceramic Type: | Normal ceramic and Anti-static ceramic |

Characteristics:

1、Stable electrostatic performance, Class A fire, sound insulation, dust and dirt

resistance, chemical corrosion resistance;

2、Strong surface wear resistance, the hardness of 7 degrees Mohs, easy to clean;

3、No deformation, no dust, strong carrying capacity, combined with ceramic

characteristics, anti-aging, the service life of more than 60 years;

4、Variety of colors, including pure white, wood grain, etc., beautifully paved,decorative;

5、OEM is available;

Applications:

Data Centers、Commercial Buildings、Educational Facilities、Clean Rooms、Control Rooms、

Libraries and places where require anti-static environment or have many wires.

Specification:

Type | Size | Concertrated Load Defleation≤2.5mm | Uniform Load | Ultimate Load | System Resistance | ||

mm | LBS | KN | KG | KN/㎡ | KN | Ω | |

FS662 | 600*600 | 662 | 2.95 | 300 | 12.50 | 8.85 | 1.0x106-1.0x109 |

FS800 | 800 | 3.56 | 363 | 16.10 | 10.68 | ||

FS1000 | 1000 | 4.45 | 454 | 23.00 | 13.35 | ||

FS1250 | 1250 | 5.56 | 567 | 33.00 | 16.68 | ||

FS1500 | 1500 | 6.67 | 680 | 34.50 | 20.02 | ||

FS2000 | 2000 | 8.90 | 906 | 46.00 | 26.70 | ||

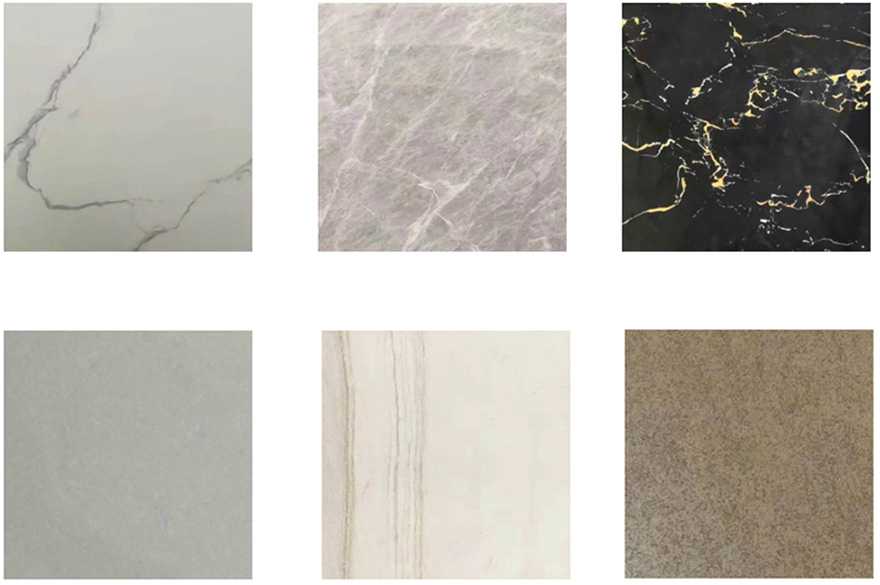

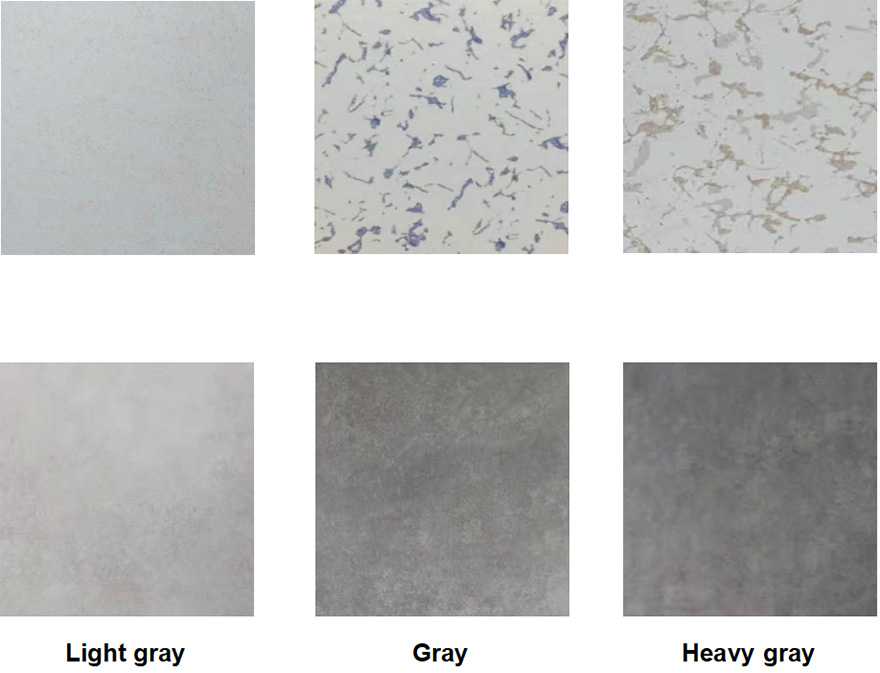

Ceramic Color

Download

Download